The company worked with the industry association to cut down transaction costs for all auto majors in India by as much as 90 per cent

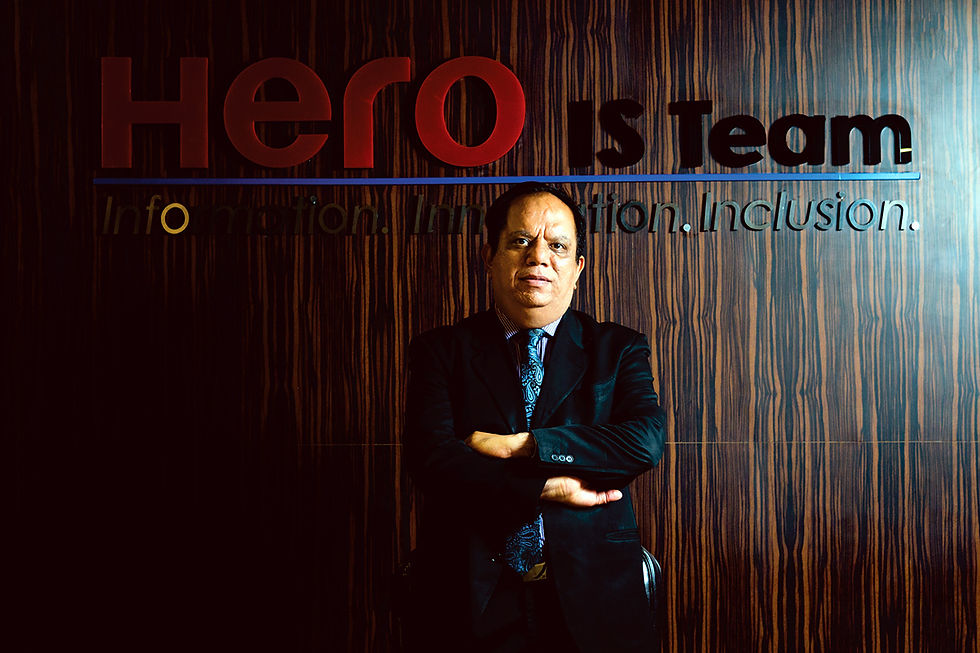

VIJAY SETHI

HERO MOTOCORP

We simulated entire plant conditions as we learnt from all other plants that simulating assembly lines, production lines and everything in a simulated environment created full digital factories. We call it 'Digital Twin'.

In the Indian automotive industry, every company has a number of suppliers, each one of whom uses their own systems, IT systems and OEMs. Organisations like Maruti, Hero and Bajaj have their own systems to interact; some do it over phones, others by emails, some by SAP and others by a combination of all. Therefore, it creates a huge amount of issue at the suppliers' end.

In 2010, Hero Motocorp CIO Vijay Sethi embarked on a journey to remove this clutter and automate the process. “We involved KPMG to build standards for us. When the second round of change took place with the management, these standards were opted by the entire automotive industry. One needed to go through all the organisations, get their views, explain to them in detail and finally somewhere in 2012, the Indian automotive industry adopted those standards,” recalls Sethi.

It took around four years to get to the standards. “We had not started implementation till then. Then we started IT implementation so we looked at various organisations who could implement it. We looked at SAP, IBM and a few others and finally selected IBM to help us use Cloud. We used IBM Cloud in February 2014 at Auto Expo to hold a press conference with SIAM and ACMA. It was the first day when we did the first transaction between Hero and one of the suppliers on this particular system,” says Sethi.

From that day onwards, Hero Motocorp started enrolling other suppliers, other OEMs and today, this is one of the systems which is helping the Indian auto industry in a big way. The company has helped reduce the cost of transaction by around 90 per cent. As a result, the error rate went down to zero per cent. And there is no manual intervention. In fact, many organisations have shut down their old systems and moved over to Cloud and the cost of managing everything has reduced significantly.

In a recent case, when Hero Motocorp was planning to setup a new plant at Halol in Gujarat, the company decided to use technology in a big way to help set it up.

“Then we learnt as to what are the issues, what are the ways in which we can streamline the entire production so that our efficiencies go up. We produce a bike on a line, every 18 seconds a bike comes out from the assembly line of the production plant. Imagine if we reduce that 18 seconds to 17.5 seconds; the amount of production efficiency increases,” he adds.

Sethi's aim is to see if the company can significantly drive value out of its IT investments. “If we spend `1-2 crore in an IT project, how can we get back `5 crore out of it is what I want,” he says. The last instance is of GST. There are a lot of companies which are struggling even today. In Hero Motocorp's case, the company started invoicing at 8 am on July 2 which means its customers did not reach the store before 9 am but it still had released its systems at 8 am. “I am happy that not even one production or sale was lost due to transition to GST. It was tough and a lot of planning went in. Twenty days prior to GST enforcement, this floor looked like somebody's wedding was on. Systems were released at our dealers' ends. All the 2,000 dealerships were running on July 1 morning,” he adds.

Entire planning went on for, at least, one year. “I am on the Board of SAP India and there the role I assumed was coordinating GST for entire India for all SAP customers. I had to work with all India organisations, not just automotive but also non-automotive and also with SAP to ensure that we get all the information in support,” says Sethi.

Comments